304 stainless steel tube intergranular corrosion tendency

The reason for the rust of the 304 stainless steel pipe is that the surface of the stainless steel has a chromium-rich oxide film (protective film) to prevent the penetration and oxidation of oxygen atoms, thereby obtaining corrosion resistance. Once for some reason, this film is continuously destroyed, the oxygen atoms in the air or liquid will continue to penetrate or the iron atoms in the metal will continue to separate out, forming loose iron oxide, and the metal surface will continue to rust. The alloy without solution treatment will not dissolve into the matrix, resulting in a low content of matrix alloy.

This material without titanium and tantalum has an inherent tendency for intergranular corrosion by adding titanium and niobium and stabilizing treatment to reduce intergranular corrosion.

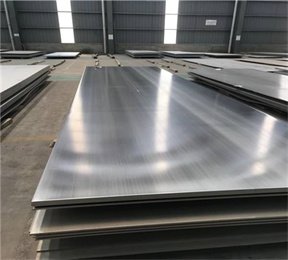

High-alloy steel can resist corrosion in air or chemical corrosive media. The stainless steel surface is beautiful. 304 stainless steel has good corrosion resistance. It does not require surface treatment such as electroplating, and it exerts the inherent surface characteristics of stainless steel. A type of steel, commonly referred to as stainless steel. Representative high-alloy steels such as 13 chrome steel and 18-8 chrome-nickel steel.

From a metallographic point of view, since stainless steel contains chromium and has a very thin surface, in order to maintain the inherent corrosion resistance of stainless steel, more than 12% of chromium must be contained in the steel. Specifications of 304 stainless steel