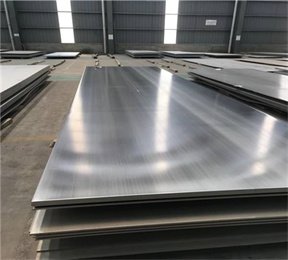

How to detect the surface quality of 904L stainless steel plate

If you want to test the surface quality of 904L stainless steel plate, you usually have to wait until the pickling process after heat treatment. The pickling process can improve the smoothness and uniformity of the surface of 904L stainless steel plate. If the surface is not cleaned well before heat treatment, the quality will not meet the standard, and it will not meet the standard after pickling. Therefore, in order to improve the surface quality of 904L stainless steel plate, surface cleaning must be carried out before or during heat treatment.

When the surface oxide scale of 904L stainless steel plate has uneven thickness, the surface roughness of the base metal surface displayed on various parts of the surface is also different, and in the pickling process, the dissolution of the surface oxide scale and the base metal at the scale attachment site The degree of corrosion by acid is not the same, so there will be uneven surface of 904L stainless steel plate.

Oil is relatively easy to adhere to the surface of 904L stainless steel plate. The thickness and composition of the oxide scale on the attached part and other parts are different, and it will also affect the carburization of 904L stainless steel plate. The carburized part is more susceptible to acid erosion.