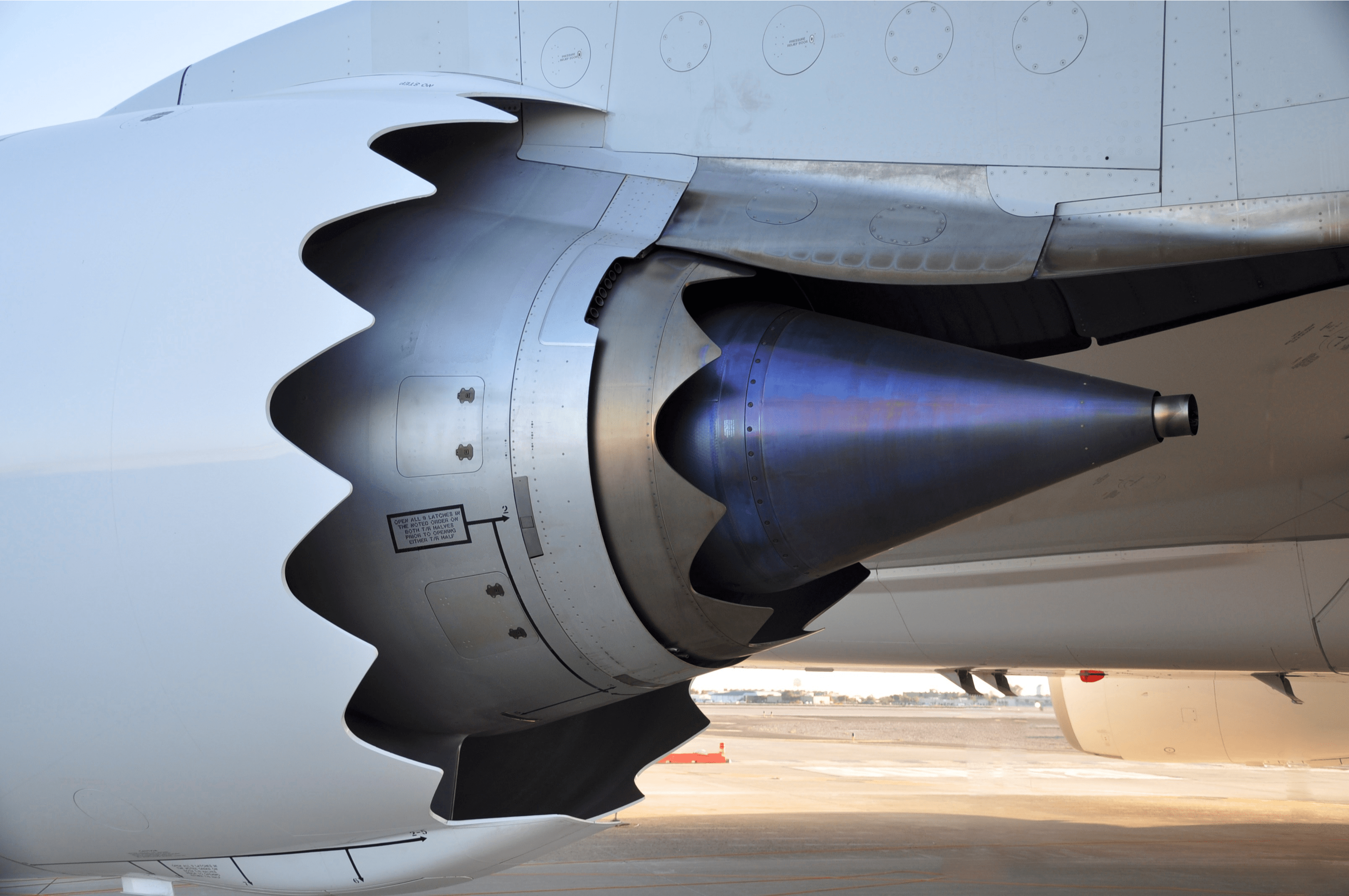

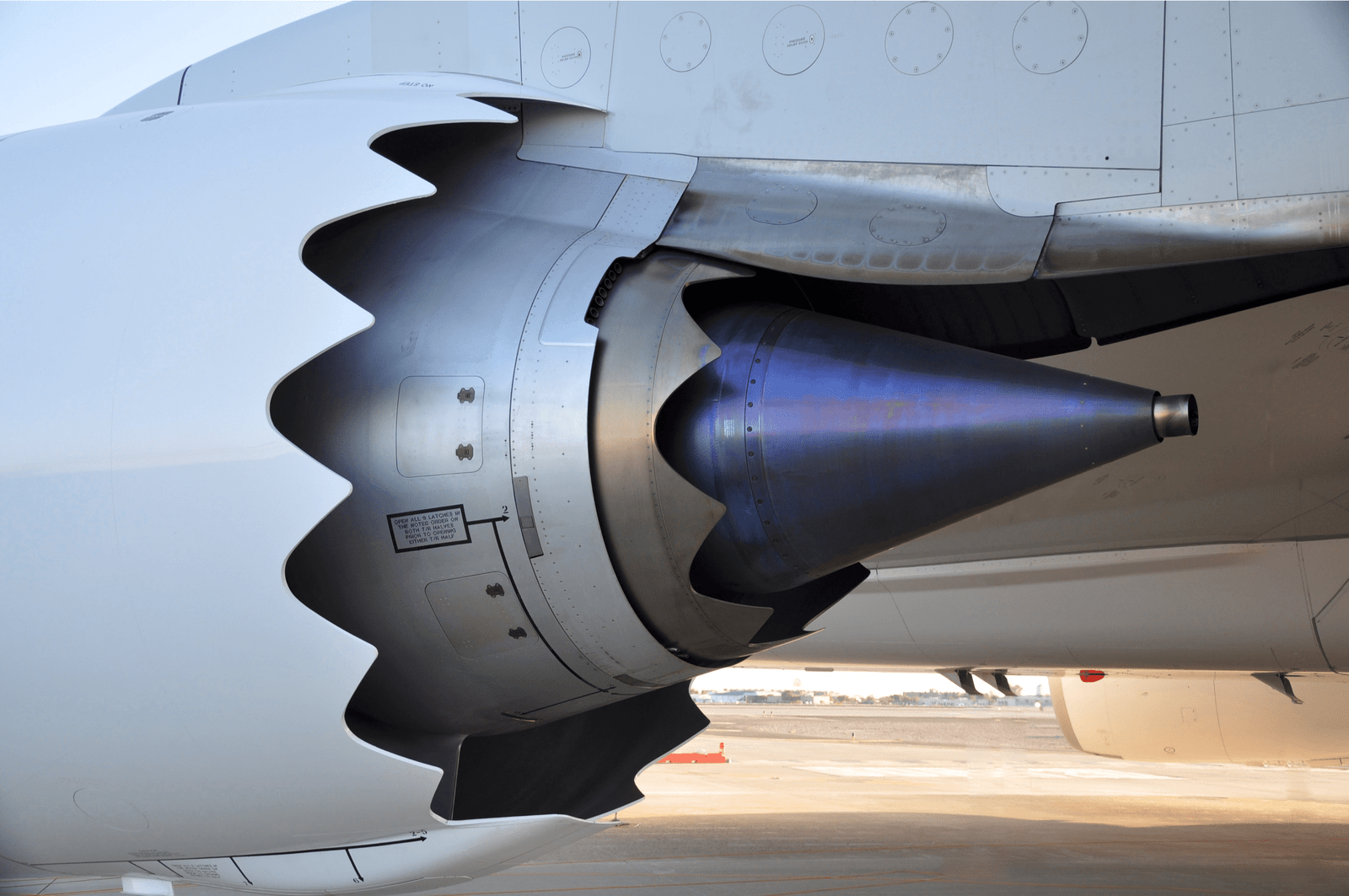

Aluminum Alloys for Aerospace

Aluminum alloys are often a preferred material for aerospace designs and required by engineering due to its corrosion-resistance properties and high strength capabilities. Compared to steel it is a lightweight option, and an ideal material for a wide range of aircraft components and aerospace applications.

Aerospace Aluminum Grades

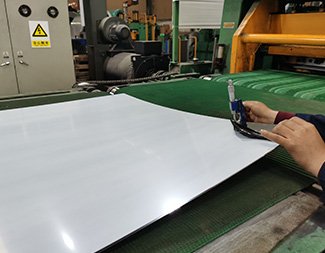

The aluminum grade needed for your aerospace application will largely depend on the function of your application. Corrosion-resistance and machinability are some of the factors to consider when choosing the correct aluminum alloy.

Aluminum Grade Aluminum Grade Properties

- Alloy 2014: Ideal for framework due to its machinability and strength. Does not provide corrosion-resistance when compared to other aluminum grades. It is not well-suited for applications with high environmental stressors or corrosive environments .

- Alloy 2024 : Widely used among aircraft and aerospace components. Provides stress resistance, high-tensile strength, and can be heat treated. Aluminum sheet and plate are ideal for applications such as aircraft wings, structures, or repair purposes.

- Alloy 3003: Provides corrosion-resistance and weldability. It is one of the more commonly used aluminum alloys for aviation and aircraft. Alloy 3003 is not heat-treatable.

- Alloy 5052: Another non-heat treatable aluminum alloy, alloy 5052 offers a high fatigue strength when compared to other aluminum grades. It offers good corrosion-resistance and formability properties. It is commonly used for aircraft fuel tanks.

- Alloy 6061: Workable with excellent corrosion-resistance, alloy 6061 can be welded and brazed. It is commonly used for wings or fuselage.

- Alloy 6063: Ideal for anodizing applications or architectural structures. Alloy 6063 offers high-tensile properties with high corrosion-resistance. Often used for aesthetic purposes and finishes.

- Alloy 7050: Ideal for wing skins and military aircraft, alloy 7050 has an excellent strength-to-weight ratio and can be heat-treated.

Benefits of Aluminum for Aircraft and Aerospace Applications

- Durability in high stressed environments, temperature and pressure extremes

- Formability allows for easy fabrication for smaller aircraft parts

- Aluminum alloys offer high electrical conductivity

- Due to the lightweight properties of aluminum, it offers a cost-effective alternative to other material types. Lighter aircraft can equate to less fuel consumption and an overall cost-saving advantage